A Journey in Rotational Moulding in Northern Africa Adara Srl

Adara Srl, of Algeria, was established in 2000, initially to manufacture PPR (polypropylene random copolymer) pipe and plumbing fittings. The company grew to become a market leader in the manufacture and distribution of plumbing fittings throughout Algeria. In 2011, after researching the market and understanding the potential for water storage, Adara decided to diversify into polyethylene water tanks and so began their rotational moulding journey.

Algeria has a classic Mediterranean climate marked by summer months with little rainfall and clear blue skies. As the largest country in Africa, Algeria is mainly made up of arid land and 80% desert. Most of its 45million inhabitants live within a coastal strip 100kms (60mi) from the Mediterranean sea. Algeria has traditionally relied on groundwater and more recently on desalinated sea water for their drinking water.

While all the countries in North Africa have been left high and dry by the longer and more intense droughts over the past couple of decades, the water shortages faced by Algeria have been made worse by the mass migration of rural Algerians to the cities within the last 10 years. Algerian cities, including its capital, Algiers, have been experiencing significant water shortages.

The Adara factory is located in Oued Alleug, about 40km south west of the capital, Algiers. It is well positioned to supply the metropolitan area of Algiers, with an estimated 5 million people, and is also central to the heavily populated Mediterranean coastal strip of Algeria.

Mr. Collu is one of the two partners who founded the company. While he was familiar with plastics and the extrusion process to make polypropylene plumbing fitting, he had little understanding about rotational moulding. His research involved a steep learning curve to understand the rotational moulding manufacturing process as well as the potential for growth in the water tank market.

After searching in Europe and Asia for suppliers of machines and moulds, Mr. Collu selected Rising Sun, from China, as his primary supplier. One of the key reasons for this decision was the ability of Rising Sun to manufacture and supply both the rotomoulding machine and the moulds as a turnkey project.

Up until COVID impacted international travel, Rising Sun would send two technicians to Adara to not only assist with the machine assembly and commissioning, but also to train Adara staff on machine operation, machine maintenance, product moulding, and basic process control. Technicians would only leave Adara after the operators demonstrated they could operate the machine to make good quality products. Due to COVID-19, Adara’s latest shuttle machine will be installed and commissioned without any technicians.

While Adara is now very familiar with the Rising Sun machines and moulds their preference is to take advantage of the skills and experience from their supplier and use it as an opportunity to transfer knowledge to their own staff.

Adara does not have an in-house design team so they rely on Rising Sun to help them develop new projects, from concept to reality.

Their first rotomoulding machine was a 3 arm carousel. Commissioned in 2012, with moulds to make horizontal and vertical water tanks from 500L to 10,000L (500g to 2,600g), but also some moulds to make other products like road barriers, and pickup truck covers. Some diversification, just in case the governments huge investments in desalination plants and other big water infrastructure softened the demand for poly water tanks.

This decision was made with the knowledge that in 2011 Algeria had already built 14 desalination plants to provide more reliable water supplies. However, in the following 10 years this big infrastructure strategy failed to stop many cities being unable to supply enough water to keep up with demand. In recent years some municipal suppliers have rationed water supplies to once a day, and in some areas only once every second day. To manage this inconsistent supply city residents have resorted in increasing numbers over the past decade to store water in tanks, jerry cans, or whatever they could afford in their houses.

In 2015, Adara introduced a line of large 25,000L (6,600g) water tanks, and by 2017, they began making 30,000L (8,000g) tanks. They now have expanded their rotomoulding equipment to 6 machines. Four carousel machines with ovens ranging from 2.5m to 4.5m (98in to 177in) and 2 shuttle machines with ovens ranging from 3.5m to 5.5m (138in to 216in). There is a 7th machine on the water from China, due to be commissioned in early 2022.

While Adara have progressively made larger and larger capacity tanks for rural and industrial customers, the most popular tank sizes are 500l, 1000l, and 1500l. They are purchased by households to be installed on balconies, basements, or roofs of buildings. These need to be small as they have to fit within restricted spaces, especially for people living in city apartments. They will typically be filled up from municipal supply, when the water is made available, so as to provide potable water whenever required.

Adara use a range of mould types, including fabricated aluminum, cast aluminum, CNC aluminum, but for water tanks the moulds are primarily fabricated steel.

The rotational moulding industry in Algeria is a thriving one, with 10 major rotomoulders and about 15 small scale rotomoulding operations scattered around the country. It suffers from the same problems familiar to many other countries. There can be a wide variation in quality between different moulders, which can create quality perception problems for the whole industry.

The decision by Adara to diversify into water tanks has proven to be a successful one. It appears that the lack of confidence by the population in the government to provide water security, combined with the long duration of the drought, has sustained growing demand for individual water security through the use of storage tanks. Adara has grown their rotomoulding business significantly during the past decade and demonstrates the possibilities of rotational moulding, continuing to satisfy the basic human needs for water security with storage tanks, complimenting high technology solutions such as large scale reservoirs, desalination, and transfer canals.

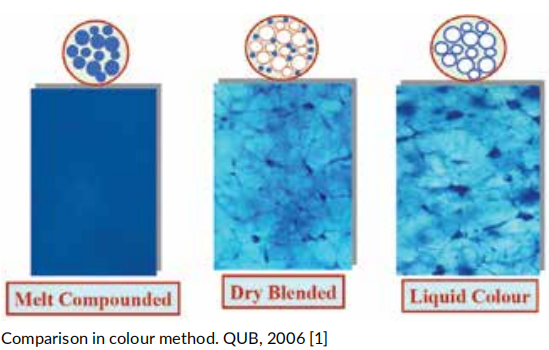

Most rotomoulders in North Africa, Middle East, and Asia manufacture and promote triple layer tanks to their customers. They typically dry blend their colours, primarily to lower their raw material cost. However, dry blended pigments will leach into the water and affect the water quality which is one reason why they need to have an inner layer of natural; to minimise the risk of contamination to the drinking water. The black middle layer will be required in most tanks because the dry blended outer colour does not inhibit light transmission through the walls, as even low light levels can promote the growth of algae inside the tank. The inner layer of natural is a cheaper material cost, and allows the customer to more easily see if the water and tank inside is clean.

With the growth in demand for tanks over the past decade there have been some moulders importing low cost and low quality polyethylene resins and dry pigments, along with making tanks with inadequate wall thicknesses. This has resulted in some poor quality tanks entering the market, with a relatively short service life.

While Adara were new to the rotomoulding industry they decided to use high quality melt compounded colours to manufacture their tanks. They were aware of the technical advantages and disadvantages of tumble blending dry pigments and melt compounding, which were being drummed into the rotomoulding industry from recognised authorities such as Queens University Belfast. Adara understood the quality benefits of using an extruder to mix colours because they had extrusion experience manufacturing their own plumbing pipe and fittings.

Their business philosophy was to manufacture good quality products, using good quality materials with good quality moulds, combined with efficient and reliable machinery to ensure the market for water tanks have a long and prosperous future. Adara import their powder in a range of compounded colours, most commonly blue, green, and grey, as well as black for the middle layer, and white for the inner layer. They mould their tanks in 3 layers because consumers have been convinced that water tanks needed 3 layers to be fit for purpose. It has been easier to present their tanks to market with the same triple layer material design, using superior melt compounded colours, to avoid the disadvantages of tumble blended pigments.

2021 was a difficult year for the rotomoulding industry in Algeria. Like almost all countries around the world they faced significant increases in the cost of polymer. This was combined with the continued growth in demand because of the drought and increasing problems supplying drinking water. The increasing prices for tanks created customer anger as some perceived that they were being overcharged because of the high demand, rather than the higher material costs.

Plastic tanks also received some bad press because some people were buying cheap second hand chemical tanks, which are not safe to store drinking water.

Algeria received large amounts of rain at the end of 2021, which fell into catchment areas allowing dams to increase storage levels significantly. This is good news for water stressed Algerians. While it may take some pressure off the municipal water supply authorities, and reduce the urgency for water tanks in the short term, it is likely that the long-term demand for rotomoulded water tanks will remain strong in Algeria.

The story of water scarcity is a growing concern across the world. Apart from Algeria, water scarcity is a problem all over North Africa, the Middle East, China, Brazil, and Australia. Even one of the world’s wealthiest countries, the United States, has suffered frequent and ongoing droughts in the southwest over the past two decades.

The quest for individual water security continues to support the growth of rotomoulded water storage solutions in Algeria and around the globe.

中文简体

中文简体 English

English Русский язык

Русский язык España

España عربي

عربي