-Specially selected auxiliary machine for rotomolding production line;

-Clean and bright colour for powder to make excellent products;

-Easy operation;

-Safe;

-Less Maintenenace with main word famous brand electric appliance.

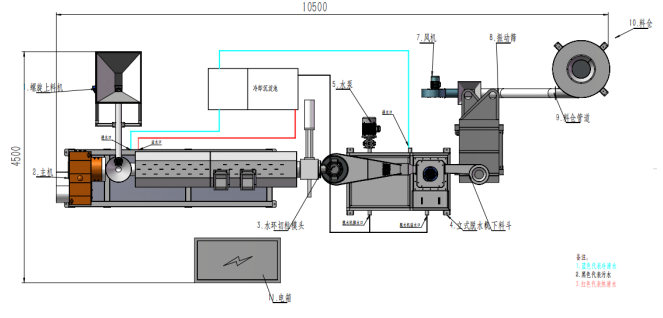

Product Name: Granulation Line For LLDPE Hard material

Model: SJ100/33/75KW LINES

Capacity:250-300KGS/hr

Feeding Method: With Top force feeder hopper

Function:Make bright colour for rotomolding raw material

Final output:

Item | Name |

1 | Screw Loader made of stainless steel |

2 | SJ100/33 Single Screw Extruder controlled by frequency converter Heat power 36 kw |

3 | Hydraulic Screen Exchanger Screen ring is made of 38CrMoAlA Alloy With pressure sensor P200 with Pressure sensor |

4 | Hydraulic station |

5 | Water Ring Granulation System S.S. Speed is controlled by inverter |

6 | Water ring cool channel S.S. |

7 | Centrifugal Dewater S.S. |

8 | Water pump for centrifuge circulation |

9 | Vibration Screen S.S. |

10 | Air Conveyor System S.S. |

11 | Silo Stainless steel S.S. |

Note: Suggest to couple with pulverizer to make rotomolding powder.